The COVID-19 pandemic has led to people refraining from going out, which has resulted in a sudden increase in demand for e-commerce sites, providing a tailwind for e-commerce mail-order businesses.

However, as a business expands and the number of orders increases, the workload of receiving orders and shipping becomes greater, and it becomes difficult to keep up...I'm sure there are many business owners who have found themselves struggling with this issue.

Improving the efficiency of the flow from order to shipment is essential for business expansion and customer satisfaction. For this reason, an increasing number of businesses are introducing OMS, which streamlines order/inventory management operations, and WMS, which reduces the burden of shipping operations.

In this article, we will explain the benefits, precautions, and key points for implementation of OMS and WMS for business operators who are having trouble with order and shipping operations.

table of contents

- Common issues in EC management

- EC-related system functions

- Benefits of Introducing OMS

- Benefits of Introducing a WMS

- OMS/WMS implementation patterns

- Key points to consider when introducing an OMS/WMS

- summary

Common issues in EC management

If you are having issues with your EC operations, you may have the following concerns:

- There is a lot of manual work, and the whole day is spent just on receiving orders, so there is no time to work on measures.

- The order taking operations are too complicated and depend on individual skills.

- Not being able to grasp inventory in real time leads to lost opportunities and excess orders due to "inventory discrepancies"

- Complex shipping instructions, such as whether or not to use set products or gift wrapping, were not communicated accurately, leading to numerous mistakes during shipping.

- Long lead times for shipments and low customer satisfaction

These are some of the most common concerns we receive from e-commerce businesses.

As the number of stores increases and the business scale grows, and as order conditions become more complex, manual work becomes insufficient.

Therefore, the key to solving this problem is to introduce an appropriate system and automate operations .

EC-related system functions

First, let's look at the process from ordering to shipping and the systems involved in EC operations.

After receiving a customer order at the online store, we carry out order management tasks, pass on shipping data to the warehouse, and then after shipping management tasks, deliver the product to the customer.

Among the systems involved in each process, the three most representative are as follows:

Cart System

This is a system for selling products in online shops and is used when building an EC site. User orders are also carried out through the cart system.

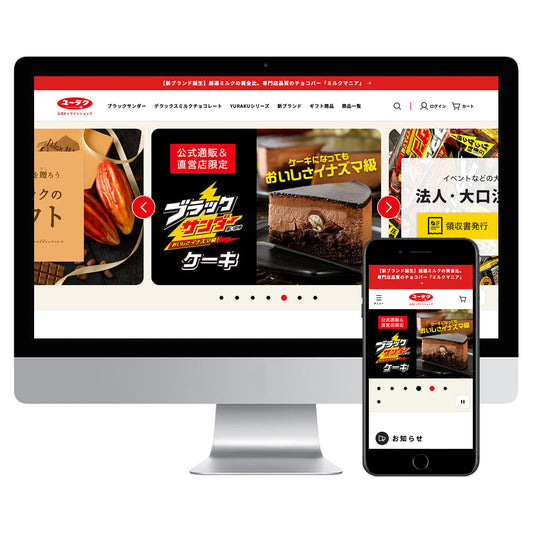

There are cart systems with various characteristics, such as in-house EC type (Shopify, MakeShop, etc.), mall EC type (Amazon, Rakuten, Yahoo! Shopping, etc.), repeat mail order type, and cross-border EC type.

OMS (Order/Inventory Management System)

An OMS (Order Management System) is a system that consolidates EC order management, inventory management, product management, etc. For EC businesses, it is an important tool for optimizing the process from order to product delivery.

This system is useful when you have multiple online stores. Since you can centrally manage product information and order details for multiple stores, using an OMS can greatly improve work efficiency .

- Order management: Managing order registration, changes, and cancellations

- Inventory management: receiving, issuing, allocation, etc.

- Payment management: Payment status and refund management

- Shipping management: Shipping instructions/cancellations, arrangements, and shipping record registration

- Product management: Managing basic product information such as product numbers and names

- Email sending: Functions for sending order confirmation emails and shipping notification emails, etc.

WMS (Warehouse Management System)

A WMS (Warehouse Management System) is a system that centrally manages warehouse operations, such as receiving, inventory, shipping, inventory, document issuance, and location, from the time goods and materials arrive until they are shipped. It is equipped with functions to support the receiving, storage, and shipping of goods efficiently and without errors. There are cloud-based and on-premise types, but recently the cloud-based type, which does not require the company to operate a server, has become mainstream.

- Receiving management: Receiving schedules, label management for incoming products, etc.

- Shipping management: Managing shipping schedules and shipping records, issuing instructions, and creating picking lists

- Inventory management: Centralized management of information such as inventory location, quantity, expiration date, and manufacturing date

- Document issuance: Issuance of labels, documents, delivery notes, and purchase orders required for inventory management

- Inventory management: Inventory instruction function and easy input by scanner, etc.

Benefits of Introducing OMS

Next, we will introduce the benefits of introducing an OMS.

Improved work efficiency through centralized management of multiple channels

The biggest advantage is that multiple sales channels can be managed with one system, reducing the amount of work required. If you do not use an OMS, if you have three sales channels (for example, Shopify, Rakuten Ichiba, and Amazon), it will take as much work as there are channels. This is because you will have to switch between each channel to manage information.

However, by introducing an OMS and managing order information centrally, you can manage it all with the OMS without having to switch channels. Another benefit is not just increased efficiency, but also the ability to compare and check sales from multiple channels all at once with the OMS.

Reducing work errors

By implementing OMS, operations from order receipt to the creation of shipping data are automated, preventing human errors.

- Importing order information

- Inventory adjustments

- Confirmation of payment for each order

- Sending order receipt emails

Optimize inventory management

When inventory is managed separately across multiple sales channels, there is a risk of missed sales, for example, a product being sold out on Amazon but still in stock on Rakuten Ichiba. The best way to sell an item is to rotate inventory from other stores, but manually adjusting inventory in real time is a huge burden for operators and prone to mistakes.

On the other hand, by introducing an OMS, you can centrally manage inventory information across stores, reducing the risk of missing sales opportunities due to stock shortages only in certain channels. You can also prevent over-orders due to inventory setting errors that tend to occur with manual management.

In this way, the introduction of an OMS can be extremely useful in preventing opportunity loss and maximizing sales opportunities.

*Points to note when installing OMS

On the other hand, it is also important to be aware of the points you should be careful about when introducing an OMS.

- Operations will need to be reorganized and training will be required .<br>Operations will need to be reorganized and restructured to suit the system, and staff will need to be trained to use the system effectively.

- There is a risk that results will not be achieved if the issues and objectives are not clarified. If you do not clarify what issues you want to solve, you may find that the system does not have the necessary functions after implementation, or the system you have worked so hard to implement may not take root, so care must be taken.

-

Implementation and operating costs are incurred <br>Unless you have developed your own OMS, using a system provided by an external vendor will incur initial and operating costs. However, when comparing implementation costs and labor costs, it seems that in the long run, implementing an OMS is often cheaper. There are also other major benefits, such as reduced management workload, shorter work hours, and prevention of human error.

In any case, it is necessary to conduct simulations before implementation to confirm the cost-effectiveness.

Benefits of Introducing a WMS

Improving shipping efficiency

With a WMS, picking lists can be automatically generated, allowing workers to efficiently collect products and prepare them for shipment. It is possible to track the entire process from receiving the products to storing and shipping, and centrally manage the status of each task. This allows workers and managers to check the progress and waiting status of tasks at a glance, and to make arrangements or give instructions as necessary.

Real-time inventory information

A WMS has the ability to track and display inventory status in real time. This can significantly reduce the time and effort required to manually check inventory and update paper-based records. It can also improve the accuracy of inventory management. It can prevent human errors and information delays that tend to occur with manual inventory management.

Reduce errors and costs

In many cases, the majority of work in logistics sites is done manually, making labor costs an issue. By introducing a system, it is not difficult to reduce labor costs by leveling out and streamlining work, leading to cost reductions.

*Points to note when introducing WMS

You should also check the points you need to be careful of when introducing a WMS, and consider whether you should introduce the system even if it will put a strain on your business.

-

If the purpose of introducing a WMS is unclear, there is a risk that the expected results will not be achieved.

Although WMS offers a variety of benefits, the necessary functions and expected results vary from company to company. If you introduce a WMS without being clear about your purpose, you may end up choosing a system with insufficient functionality or not achieving the desired results, so you need to be careful. - The implementation itself is costly and time-consuming. <br>Implementing a system incurs implementation costs, as well as the time required to organize operations and train staff.

OMS/WMS implementation patterns

We found that while both OMS and WMS have their advantages, it is necessary to choose a system that is appropriate for the size and requirements of your business.

So how are they actually being implemented in EC sites? Let's take a look at the appropriate implementation patterns for each.

If you have not installed the system

| Number of stores | 1 store |

| Order size | The number of orders is small and there are no complicated order conditions |

| Shipment Quantity | Less |

Basically, order management is done manually. In many cases, the scale of business is small and everything from order receipt to shipping is done in-house. If the burden of manual work becomes too great, such as when the number of stores or orders increases, you should consider introducing an OMS. In addition, outsourcing shipping operations will allow you to free up time to focus on measures to increase sales.

WMS only

| Number of stores | 1 store |

| Order size | No complicated order conditions |

| Shipment Quantity | Large number of SKUs and shipments |

Since there is no OMS installed, it is suitable for cases where there is only one store and no complicated order conditions. In cases where there are a large number of SKUs or shipments, shipping operations are outsourced to warehouse operators or agents, and a WMS is installed there. In some cases, the cart system and WMS can be linked via API, but basically order management operations are done manually. If the number of stores increases or the number of complicated order conditions increases, it is time to consider installing an OMS.

OMS only

| Number of stores | Multiple stores |

| Order size | We can handle large numbers of orders and complex order conditions. |

| Shipment Quantity | Fewer SKUs and fewer shipments |

It is assumed that the cart system and OMS are linked, but it can also handle inventory management for multiple stores and complex order conditions. Shipping operations are often performed in-house, but if the number of shipments increases, it is a good idea to consider outsourcing to an agent or introducing a WMS.

OMS and WMS introduced

| Number of stores | Multiple stores |

| Order size | We can handle large numbers of orders and complex order conditions. |

| Shipment Quantity | Large number of SKUs and shipments |

In cases where the OMS and WMS are implemented as separate systems, the key point is the integration between the OMS and WMS systems. If there is little data that can be integrated, the order clerk will have to do manual work such as modifying the CSV to match the WMS specifications, which will reduce the amount of automation and the benefits of implementation.

Introduction of integrated OMS/WMS

| Number of stores | Multiple stores |

| Order size | We can handle even complex order conditions |

| Shipment Quantity | Large number of SKUs and shipments |

In this pattern, OMS and WMS are integrated. Since it is a single system, there is no need to consider linking between systems, which allows for more seamless operation and makes it possible to almost completely automate the flow from order to shipment.

*Note

Introducing an OMS alone will not lead to all operational efficiency improvements or error prevention in e-commerce operations. Identify the issues you are currently facing and confirm whether they can be resolved by OMS alone or whether introducing a WMS is also a good idea. If the issues cannot be resolved by OMS alone, we recommend that you consider introducing a WMS in parallel or outsourcing shipping operations to a logistics agent. You may also want to consider an "OMS + WMS integrated" service that can further automate the flow.

Key points to consider when introducing an OMS/WMS

When introducing an OMS or WMS, here are four points to consider when choosing the system that best suits your company.

Does it match the scale of your business? Can it solve the problems you are facing?

It is essential to check whether the system matches the scale of your business and the issues you are facing. If you introduce a system that does not match the scale of your business, there is a risk that it will be expensive. In addition, since the functions and effects of both OMS and WMS vary depending on the system, if you do not check before introducing it, you may end up in a situation where you are unable to solve the issues you are facing. Be sure to organize your issues in advance and check whether the system has the functions that will lead to solving them.

Is it possible to link with the system I'm using?

It is very important that the OMS you plan to introduce can be linked to your current mall or cart system. Also, if you are using a warehouse or shipping agent, be sure to check in advance whether it can be linked to the WMS or other system they use. If neither of them can be linked smoothly, extra costs and operations will be incurred, and ultimately business efficiency may not be achieved.

It is important to organize which parts of the systems you are already using can be changed and which parts are fixed, and then use the immovable systems as a starting point to consider introducing or modifying other systems .

Is the system easy for field staff to use?

While a system with a wide range of functions is attractive, the more complex it is, the greater the risk that on-site staff will not be able to use it properly. If you choose a system with an easy-to-use management screen, you can proceed smoothly even after implementation.

Is the system cost-effective enough to recover the costs of implementing it?

With an OMS, if the number of orders is small or if you do not operate multiple stores, some systems may be expensive. The same is true for a WMS, so be sure to understand the costs associated with implementation in advance and perform a cost simulation of actual implementation.

summary

In today's world, where channels have diversified due to the expansion of the e-commerce market, it has become realistic to centrally manage them using systems such as OMS and WMS.

When selecting an OMS or WMS, it is important to clarify the scale of your business, as well as your challenges and requirements, and then choose the most appropriate system.

Our company mainly uses LOGILESS, an integrated OMS/WMS.

For more information about LOGILESS, please see the following article:

Realize automated shipping with an integrated OMS/WMS! The benefits of implementation that only an EC manager can tell you

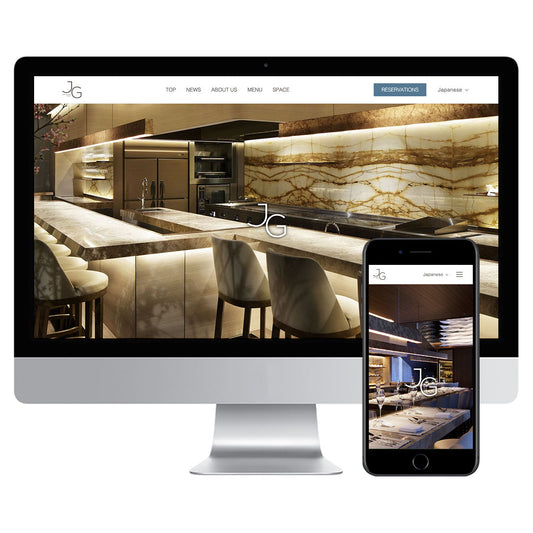

In addition, we have experience in operating various EC sites, so we can provide construction, operation support, and consulting. We will propose the optimal system environment based on the current system environment and issues that EC businesses are facing.

If you are a business owner who has issues with EC management, please feel free to contact us.